T10 Steel Swords

Discover the Strength and Artistry Behind T10 Swords

Let’s be honest – not every sword earns a place on your wall or in your hands. But T10 swords? That’s a different story entirely. At BudK, we’ve curated a lineup that’s less about hype and more about heritage, steel quality, and performance that speaks for itself. Whether you’re building a collection with purpose or finally grabbing that piece you’ve been eyeing for months, we’ve got options that hit the mark.

T10 Swords Deliver the Edge Serious Collectors Crave

When it comes to steel that holds up under pressure and ages with grace, T10 is in a league of its own. This high-carbon tungsten alloy isn’t just a mouthful of metallurgical jargon – it’s what gives these blades their unmistakable bite and polish. We’ve seen firsthand how well this steel performs, from mirror-smooth edges to intricate hamons that aren’t just decorative – they’re a testament to real tempering skill. You’ll notice the difference immediately, especially if you’ve handled lesser blades before.

View Sword Collection:

Explore the Musashi Line of T10 Swords

We’ve carried Musashi for years, and there’s a reason they keep selling out. These blades walk the line between tradition and affordability without cutting corners. Musashi’s T10 katanas often feature clay-tempered finishes and real hamons – not etched imitations. For collectors who want authenticity without taking out a second mortgage, this line has become a go-to. We’ve had clients tell us that their Musashi katana quickly became the centerpiece of their display, and frankly, we’re not surprised.

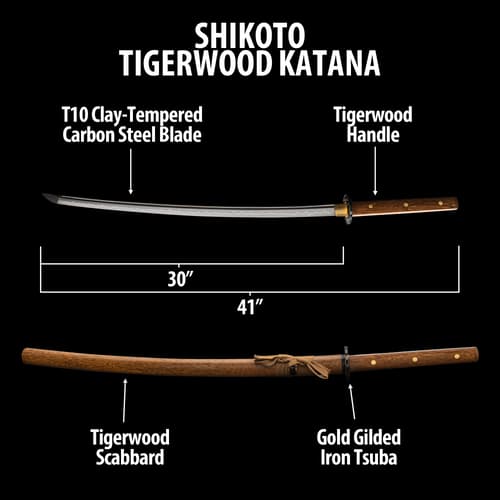

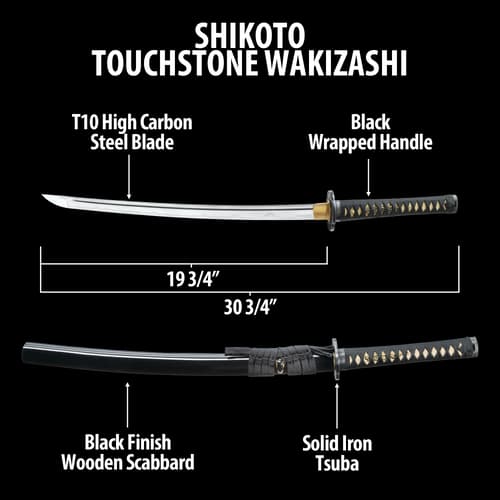

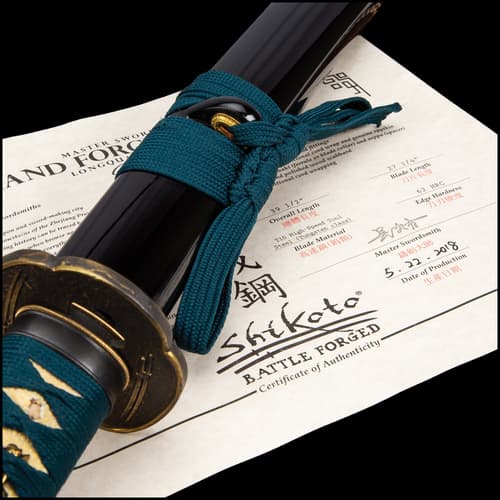

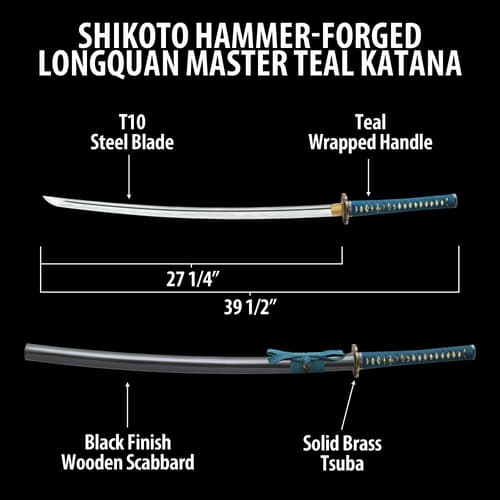

Shikoto Blends Tradition and Precision in Every Sword

There’s a quiet elegance in a Shikoto blade – a kind of restrained confidence that comes from clean lines, hand-forged steel, and thoughtful construction. The full-tang design offers peace of mind, while the ray skin wraps and ornate fittings strike a chord with anyone who appreciates the finer things. Shikoto swords aren't loud about their quality – they let the craftsmanship do the talking. We recommend these to those who want their display to reflect both heritage and refined taste.

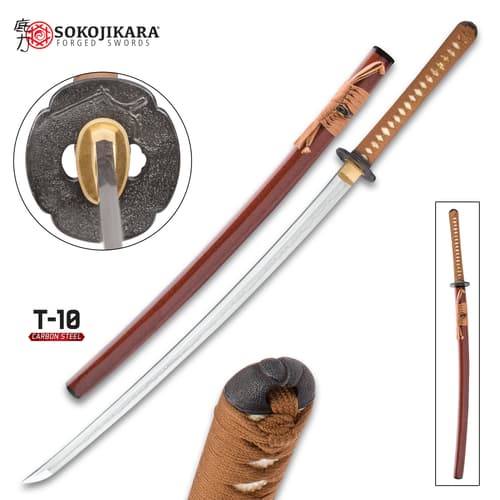

Sokojikara’s T10 Swords Are Forged with Intention

If subtlety isn’t your style, Sokojikara answers with bold silhouettes, textured fittings, and blades that exude presence. There’s something raw and unapologetic about their design language. These are swords you feel when you hold them – both in weight and energy. They favor iron tsubas, deep etchings, and substantial scabbards that let the blade shine even when sheathed. For someone who wants their sword to be as much a conversation starter as it is a collector's piece, Sokojikara delivers.

Browse Sword Categories:

Craftsmanship Matters in Every T10 Blade We Carry

Let’s not sugarcoat it – in a market flooded with flashy lookalikes, real craftsmanship is harder to find than it should be. That’s why we’re meticulous about what we stock. Our T10 selections go through rigorous evaluation – from balance to tang fitment to hamon authenticity. If a blade doesn’t meet our standards, it doesn’t make the cut. Simple as that. We’re not just selling swords – we’re offering pieces that reflect centuries of forging tradition, made accessible for the modern buyer.

Why T10 Steel Continues to Impress Discerning Buyers

There’s a reason T10 steel keeps showing up in high-tier collections and forums where enthusiasts gather. It’s not just about the edge – although that’s certainly part of it. It’s about how the steel responds to tempering, how it wears over time, how it resists deformation even after repeated use. We’ve heard from buyers who initially picked up a T10 blade as a “step up” and then never looked back. It’s not hype – it’s just a better kind of steel, and it rewards attention to detail.

Shop Sword Selection:

Explore Our Full Range of Blades with Confidence

At BudK, we’re not here to throw a hundred lookalike swords your way and hope you pick one. We’re here to help you make a choice you’ll feel good about – today and years down the line. Whether you're adding to a seasoned collection or just starting out, our curated lineup from Musashi, Shikoto, and Sokojikara is packed with blades worth talking about. We’ll walk you through the materials, finishes, and details that matter – and we’re always happy to offer honest advice if you’re on the fence.

Frequently Asked Questions

- What is T10 steel, and what makes it special?

T10 is a high-carbon tungsten steel known for its extreme hardness, edge retention, and responsiveness to tempering techniques like clay hardening. - Is T10 better than other carbon steels like 1060 or 1095?

In many ways, yes. T10 holds an edge longer and offers better wear resistance, though it does require mindful care to protect against rust. - Do your T10 swords include a real hamon?

Many of them do – especially clay-tempered models from Musashi and Shikoto. These aren’t etched but naturally formed during the hardening process. - What’s the best way to display a T10 sword?

We recommend using a proper stand or rack, ideally in a low-humidity room, to maintain both the blade and the polish over time.